Designing Your Plate Rack Cabinet: How To Make A Plate Rack Cabinet

Designing a plate rack cabinet for a small kitchen requires careful consideration of space and functionality. The goal is to maximize storage while minimizing the cabinet’s footprint. This section will Artikel design considerations, material choices, and construction details for a compact yet efficient plate rack cabinet.

Cabinet Dimensions and Material Choices

A suitable size for a small kitchen plate rack cabinet might be 36 inches tall, 18 inches wide, and 12 inches deep. These dimensions allow for ample plate storage without overwhelming a small space. The cabinet could be constructed from readily available materials such as pine, maple, or birch plywood. Reclaimed wood offers a rustic aesthetic and sustainable option. The choice will impact both the final look and the overall cost. Using plywood offers a cost-effective solution and provides stability, while solid wood offers a more luxurious finish but at a higher price point. Hardware, such as hinges, knobs, and shelf supports, should be chosen to match the overall aesthetic and durability requirements.

| Material | Quantity | Size | Cost (USD) |

|---|---|---|---|

| Birch Plywood (1/2″) | One 4’x8′ sheet | 48″ x 96″ | $60 |

| Pine Trim (1×2″) | 10 linear feet | Various | $15 |

| Hinges | 2 | 3″ | $5 |

| Knobs | 2 | 1″ | $4 |

| Shelf Supports (adjustable) | 4 | N/A | $12 |

| Wood Glue | 1 bottle | N/A | $8 |

| Wood Finish | 1 quart | N/A | $20 |

| Labor (estimated) | N/A | N/A | $100 |

| Total Estimated Cost | N/A | N/A | $224 |

Note: Prices are estimates and may vary depending on location and supplier. Labor costs are estimates based on a DIY project; professional installation would significantly increase this cost.

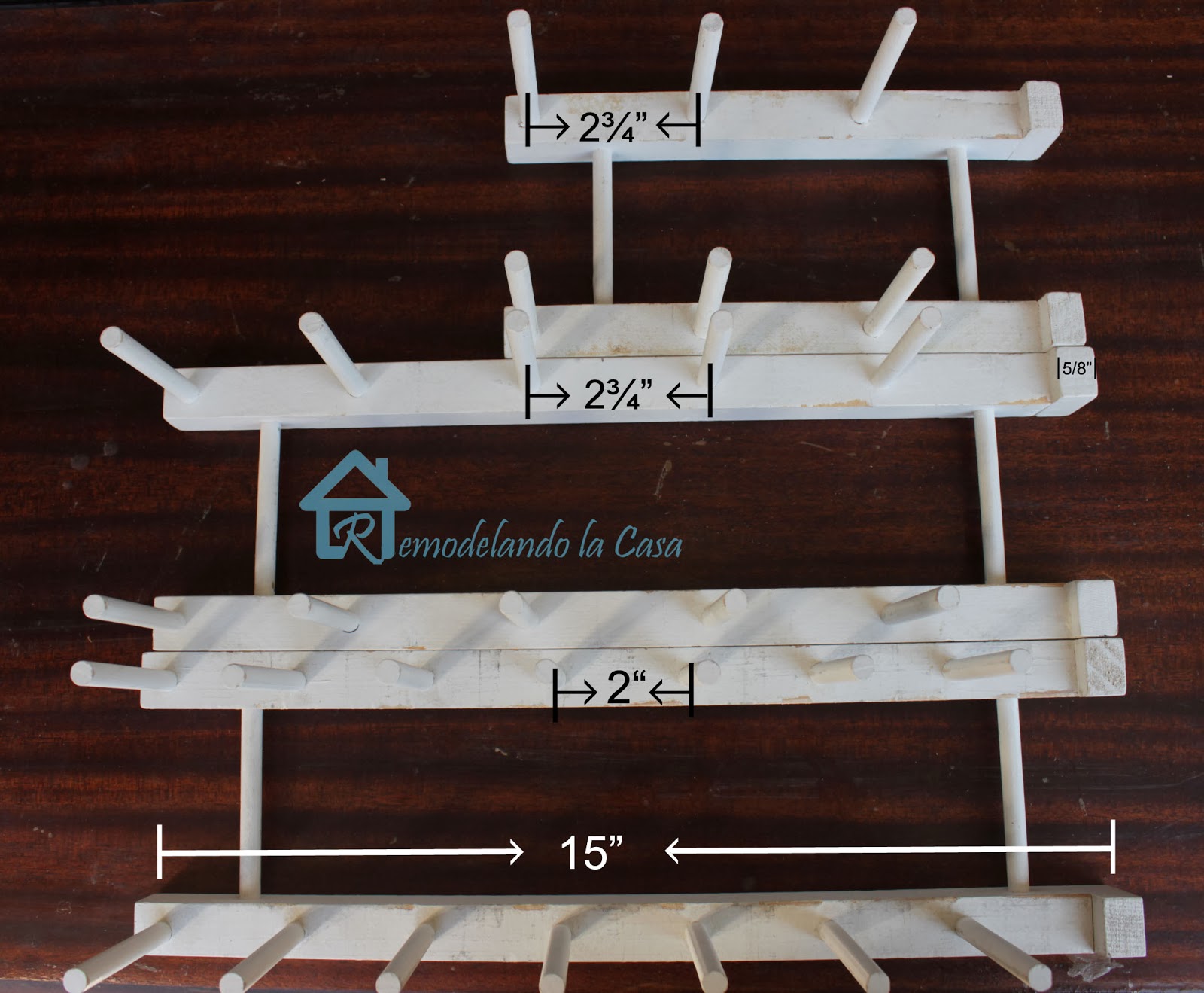

3D Model Description: Adjustable Shelves

The plate rack cabinet will be a simple rectangular box with adjustable shelves. The cabinet’s sides, top, and bottom will be constructed from plywood. The back can be made from thinner plywood or even hardboard for cost savings. The front will feature a door with hinges and a knob. The key design element for adjustability is the use of shelf supports with adjustable pins. These pins would slide into pre-drilled holes in the cabinet sides, allowing shelves to be positioned at various heights. This modular design accommodates different plate sizes and allows for customization based on the user’s needs. The shelves themselves can be made from the same plywood as the cabinet sides or a slightly thinner material for weight reduction. A simple dado joint could be used to create a secure and flush connection between the shelves and the supports.

Reclaimed Wood Parts List

This parts list assumes the use of reclaimed wood, which may require more careful selection and cutting due to variations in size and condition. Dimensions are approximate and should be adjusted based on the actual reclaimed lumber available.

| Material | Quantity | Size (inches) | Notes |

|---|---|---|---|

| Reclaimed Wood (Sides) | 2 | 36 x 12 | Thickness depends on board availability; aim for at least 3/4″ |

| Reclaimed Wood (Top) | 1 | 18 x 12 | Same thickness as sides |

| Reclaimed Wood (Bottom) | 1 | 18 x 12 | Same thickness as sides |

| Reclaimed Wood (Back) | 1 | 36 x 18 | Can be thinner than sides; 1/4″ – 1/2″ |

| Reclaimed Wood (Shelves) | 3 | 16 x 10 | Adjust quantity and size based on needs; consider thickness of 1/2″ |

| Reclaimed Wood (Door) | 1 | 16 x 12 | Thickness should match cabinet sides |

Advanced Plate Rack Cabinet Techniques

Creating a truly exceptional plate rack cabinet involves moving beyond basic construction and incorporating advanced techniques to enhance both functionality and aesthetics. This section delves into methods for adding decorative elements, explores suitable wood types, and provides a revised, AI-independent guide to building your cabinet.

Decorative Techniques for Plate Rack Cabinets, How to make a plate rack cabinet

Elevating the visual appeal of your plate rack cabinet involves careful consideration of decorative elements. Carving and inlay work are two prominent methods offering unique aesthetic possibilities. Carving allows for three-dimensional designs, while inlay introduces contrasting materials for intricate patterns.

How to make a plate rack cabinet – Carving: This technique involves removing wood to create raised or recessed designs. Simple carvings might consist of geometric patterns or floral motifs, while more complex designs could depict scenes or landscapes. The depth and intricacy of the carving depend on your skill and the tools available. A well-executed carving adds depth and texture, enhancing the overall aesthetic. For example, a simple leaf pattern carved around the edges of the shelves would add a touch of elegance. More ambitious projects could feature elaborate floral swags or even stylized animal figures. The tools needed range from basic chisels and gouges to more specialized carving tools, depending on the complexity of the design.

Inlay: Inlay involves embedding contrasting materials into the surface of the wood. This can include other types of wood (creating a contrasting grain pattern), bone, mother-of-pearl, or even metal. Geometric patterns are popular choices, as are more complex floral or abstract designs. Inlay work requires precision and patience, as the inlaid pieces must be carefully fitted and secured to prevent them from becoming loose or falling out. A beautiful example would be using dark ebony wood to create floral patterns within a lighter maple cabinet. The contrast in color and grain creates a striking visual effect. Precision is key, and specialized tools like inlay saws and chisels are necessary.

Wood Selection for Plate Rack Cabinets

The choice of wood significantly impacts the cabinet’s durability, appearance, and workability. Different wood types possess unique properties making them suitable for specific aspects of the project.

Hardwoods: Hardwoods, such as oak, maple, cherry, and mahogany, offer superior strength and durability. Oak, known for its strength and resistance to wear, is a popular choice for structural components. Maple’s fine grain and smooth finish make it ideal for decorative elements and surfaces where a polished look is desired. Cherry’s rich reddish-brown hue adds warmth and elegance, while mahogany provides a luxurious, dark finish. The choice will depend on personal preference and budget, as hardwoods generally command a higher price than softwoods.

Softwoods: Softwoods like pine and fir are more readily available and less expensive. Pine, with its easily worked grain, is suitable for less demanding parts of the cabinet. However, softwoods are generally less durable and more prone to scratches and dents compared to hardwoods. Therefore, they might be better suited for less visible areas or for projects where budget is a primary concern. Proper finishing is crucial to protect softwoods from wear and tear.

Revised “How to Make a Plate Rack Cabinet”

This guide provides a step-by-step approach to building a plate rack cabinet without reliance on AI-generated instructions.

1. Planning and Design: Begin by sketching your design, determining dimensions, and selecting your wood. Consider the number of plates you’ll store and the overall style you desire. Choose appropriate wood based on its strength, appearance, and your budget.

2. Cutting and Assembling: Accurately cut the wood pieces according to your design using appropriate tools (hand saws, miter saw, etc.). Assemble the cabinet using joinery techniques like mortise and tenon, dowels, or pocket screws. Ensure all joints are tight and secure for a sturdy structure.

3. Shelf Installation: Install shelves, ensuring they are level and securely attached. Consider the weight of the plates when determining shelf spacing and support. For added strength, use shelf supports or brackets.

4. Finishing: Sand all surfaces smooth, paying attention to corners and edges. Apply a finish such as paint, varnish, or stain to protect the wood and enhance its appearance. Multiple coats are recommended for durability.

5. Installation: Once the finish is dry, carefully install the cabinet in its intended location. Secure it to the wall for added safety, especially if it is tall or heavily loaded.